Ferro-alloys briquettes for cupola furmnaces

The briquetting of ferro-alloys for the cupola process provides these benefits:

- One very important from the point of view of our life on Earth by managing waste materials including ferro-alloys in their composition such as small fractions from crushing processes or slags,

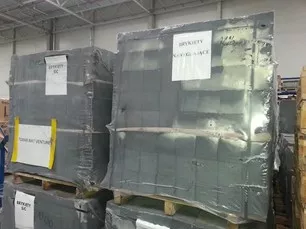

- Briquetted ferro-alloys have an answer in a shape convenient for devices loading these briquettes into cupolas, their strength preventing the briquettes from crumbling in contact with scrap metal when loaded into the cupola and moving the charge inside the cupola, and weight allowing the briquettes to pass the slag zone and immerse entirely in the molten metal, and the precise weight of the basic raw material in the briquette – usually 1kg of the basic element for briquettes of rectangular shape (cubes)

- Briquetted waste materials have a beneficial influence on the economics of cupola processes due to their significantly lower price as compared to the same raw materials of the first grade.

A common binder in ferro-alloy briquetting is cement, which is free calcium that reduces the amount of limestone used.